The Original Just Got Better

In 1964, Geringhoff introduced the world's first horizontal chopping, lawnmower style chopping corn head to the market. This head became a classic, and lead the way for other manufacturers to develop their own take on the classic Geringhoff head.

While many of our customers have moved to the Rota Disc head, for it's ability to shred and distributes smaller, more evenly sized residue, with lower horsepower requirements, some people still like the look and feel of our classic lawnmower head--the Horizon Elite XL

Technology

Similar in design to the NorthStar Elite XL, the Horizon Elite XL features a low weight design, maximum performance, the ability to disengage the chopper, and carries with it the Geringhoff reputation of a low maintenance, high quality machine. Low operating costs and minimum maintenance ensure a fast return on investment.

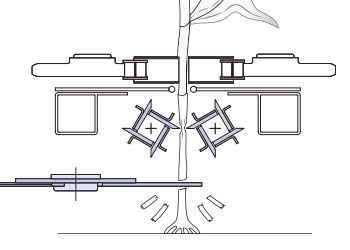

Row Unit - Bottom

1. Hardened Spiral Rolls

- Aggressive design pulls stalks in from any angle

2. Parallel Knife Rolls

- Minimal tolerance creates an aggressive crimping action that cuts through 98% of the stalk

- Adjustable and replaceable working edges to minimize repair cost and time

3. Single Component Design

- The only row unit without a frame

- All components are secured around the gearbox

- Excellent access for service

4. Hydraulic Deck Plates

- Regulated at any time from the operators seat

- Fewer moving parts

- Easy to clean and low maintenance

- No freezing in cold weather

- In cab digital monitor indicates the shaft speed and stripper plate positioning

- Design and additional wear edges minimize kernel loss

- Wide mouth and rounded stripping edges minimize crop damage

- On the go adjustment to maintain optimum performance while minimizing cob loss further increasing your yields

5. Cutting Blades

-

No extra need for a stalk chopper

-

Can be disengaged

6. Blade Attachment

-

Safety clutches to protect against damage from foreign objects

7. Vine Knife

- Prevents wrapping of tough material

- Minimizes excessive wear and damage to other components

8. Additional Working Edges

-

Low roller tolerance strips the ears very close to the stalk. In dry conditions, keeps less trash in the combine and more to the ground

-

Minimizes wear for knife roll edges

9. Aluminum Gearbox

-

“Bullet proof” reliability

-

Design proven by over a decade of use

-

Protection and drive on every row unit

-

Lightweight

-

Internal slip clutch

-

Minimal maintenance (500 hour oil change)

Row Unit - Top

10. Poly Return Sprocket

- High density lightweight design

- Reduces wear on gathering chain

- Increased diameter for greater exposure to crop

- Efficient gear ratio to bottom drive sprocket

- Exceptional picking characteristics

11. Automatic Chain Tensioner

- Eliminates excessive chain wear

- Chain tension regulated automatically

- Automatic compression resists chain damage from foreign objects

- No screws to adjust

12. Beveled Drive Sprocket

- One of three components of the gathering chain slip clutch

- Extends chain life by allowing free movement when obstructed

- Works in conjunction with the automatic chain tensioner and internal gearbox slip clutch

- Proven by over 20 years of use

13. Gathering Chains

- Heaviest gathering chain on the market

- Unique posi-loc lug design effectively gathers stalk

- Exceptional functionality and durability

ICF System

Max Flow Trough

Advanced genetics and yield increases have created new demands on the header's crop flow and capacity characteristics. Reducing cob bounce and shatter, as well as efficiently moving trash, are the achievements of the Elite XL Series massive auger trough.

Variable Auger Positioning

Advanced genetics and yield increases have created new demands on the header's crop flow and capacity characteristics. Reducing cob bounce and shatter, as well as efficiently moving trash, are the achievements of the Elite XL Series massive auger trough.

Roller Chains

Aggressive yet gentle feeding, Geringhoff offers the industry's toughest gathering chains. Nine posi-loc lugs create an efficient and durable transfer of the crop from field to stripper plate. Tremendous reliability and unrivaled performance acre after acre.

Auger Pitch

Elite XL headers offer a swift and efficient transfer of your crop. The varied pitch of the fins gently moves your yield along the outer wings then increases flow as material advances towards the feeder house. The auger's balanced combination of pitch, paddle, size, and speed reduces fluff build up, maximizes your yield and reduces operator fatigue.

Adjustable Deck Plates

The Elite XL operator has full control over the positioning of the ICF System deck plates. Controlled from within the cab, the deck plate monitor advises current gap settings and allows one touch adjustment on the go. Proven reliability in the toughest conditions over tens of thousands of acres, year after year.

Poly Angle Adjustment

Geringhoff's poly angle can be easily adapted to your specific needs. Fine tune the angle of your snouts to match crop conditions. Simply turn the adjustment knob to achieve infinitely variable adjustments without the need for tools.

ICF Sweeper

Rely on the ICF Sweeper to power you through even the toughest conditions when all others have come to a halt. Substantially increase speeds and yield in any condition and reduce your combine hours up to 50%. An integrated design offers a clean, sleek appearance with convenient fore/ aft and up/down adjustments at the touch of a button. Detaches quickly if you prefer but you’ll learn that an ICF Sweeper is the future of corn harvest.

End Row Augers

Proven to enhance feeding and be more efficient than any end row shield, the optional Elite XL End Row Augers create confidence in any tough or tall crop conditions. In-cab control reduces crop loss as well as bunching and lodging.

Folding

Folding Components

Aluminum Gearbox

Powering the Elite XL Series is a maintenance free sealed oil gearbox, which utilizes an internal self adjusting slip clutch to protect all moving parts of the row unit. Designed to be as relentless as the people who use it, these gearboxes are ready for the demanding challenges you send its way. So bring it on.

Drive Hub

The Geringhoff system eliminates undue stress on the bearings and drive mechanism of each row unit. A positive transfer of power and torque across the entire machine is created with the flex plate row coupler. This design also allows quick and individual removal of any row unit, should service be required.

Triple Protection System

Eliminate down time. Spend more time harvesting and less time on repairs and adjustments. This is the goal of the Triple Protection Slip Clutch System. Each row unit features automatic gathering chain tension adjustment, unique beveled sprockets and a slip clutch with an additional double bearing in every row unit gear box. Enter the field with confidence knowing you have triple protection on your side.

Industry Leading Coverage

Geringhoff offers an industry best comprehensive 12 months parts and labor warranty with all machines. As a bonus, immediately after registering your head with us, we automatically extended your warranty to 24 MONTHS.

For additional peace of mind, add Harvest Guard Extended Coverage to your machine and enjoy coverage up to the 60th MONTH.

Overview

What sets us apart?

Low horsepower draw - Low operating costs - The quietest, smoothest running head in the industry - Direct drive, with PTO coupler, not chain in oil bath - Modular component design for ease of maintenance and long life

Engineered to minimize ear shatter and bounce - Bullet proof aluminum gearboxes - Triple slip clutch protection on each row unit - Shock restriction couplers prevent torque loss between row units - Low profile for superior feeding in down corn - Modular poly snout design does not require sub frame - Spring loaded snouts for superior height control - Easily adjust poly angle without tools - Poly lift assist gas shocks for convenient maintenance and cleaning

The industry’s strongest and most robust gathering chain - 9 lug chains for optimum feeding - 30 second chain removal tool included - Large chain return sprocket for superior feeding and flow - Poly chain return sprocket enhances gathering chain life

Double acting hydraulic deck plates with chromium reinforced leading edge - Easily adjust auger height as field conditions dictate - Variable pitch auger flight to improve crop flow - Large auger trough to accommodate increased yields

Recognized as #1 in yield retention of all corn heads - Ability to accommodate even the toughest down corn conditions - Trash deflector evenly distributes stalk residue through the field - Easily modified to accommodate change in combine brand or model

Annual updates available as new combines are introduced - Hundreds of trained dealers across North America - Factory service technicians located throughout North America - Around the clock harvest season support

Industry leading 2 year limited warranty - Exceptional parts availability throughout North America - Consistently rated as the industry’s highest re-sale - Online and 1-800 service support - Over 130 years of harvest experience - Recognized as the world specialists in corn harvesting headers

Headsight Leveling System

Precise header height control over all types of terrain. At the heart of the Headsight header height control system are flexible poly paddles and reliable electronics. Other systems will dig in to the soil and damage the system when in reverse, but not Headsight. It's design is operator friendly and has been used reliably for decades.

Sunflower Adapter

Optional components affordably convert your Geringhoff into an industry leading Sunflower Harvester. Each row receives a cutting knife, ear extensions, and filler plate for maximum yield retention. Add back and side screens to the frame for the ultimate Sunflower harvesting header.